The production of algae, especially Spirulina, is a careful process that requires precision and control. Spirulina is a nutritious superfood known for its high protein, vitamin and mineral content. The production process of Spirulina in a controlled environment ensures that the product is of high quality and safe for consumption. In this article, we will take you through the technical steps of Spirulina production, from growth in photobioreactors to the final product in powder form.

Step 1: Grow in Photobioreactors

The Spirulina production process begins in photobioreactors. These are specialized growth environments where the algae can thrive under controlled conditions. The photobioreactors provide the ideal environment for the algae to grow, with a combination of carefully controlled light, temperature, and nutrients.

In these reactors, Spirulina is exposed to sufficient light, usually through LED lamps that stimulate photosynthesis. The water in the reactors is enriched with essential minerals such as nitrogen, phosphorus and potassium, which are crucial for the growth of the algae. The reactors are closed systems, which means that they are protected from outside contamination, ensuring a food-safe environment.

Step 2: Harvest

Once the Spirulina has reached an optimal density, a portion of the algae is removed from the photobioreactors for harvesting. This process is done to ensure that the algae do not become overcrowded and that they continue to grow. Harvesting is usually done by removing a portion of the algae mass, while the rest continues to grow in the reactor.

The photobioreactor is then replenished with fresh water and minerals to stimulate the growth of the remaining algae. This cycle process ensures continuous production of Spirulina, with the reactors never completely empty and always containing a growing supply of algae.

Step 3: Separation of Water and Algae

The next step in the production process is to separate the algae from the water. This is done using a vibrating screen. The vibrating screen is a device that uses vibrations to separate the algae from the water. The algae are collected on the screen, while most of the water is filtered through the screen and can be fed back into the system or discharged.

This separation step is crucial because it prepares the algae for further processing steps without leaving them in aqueous form. It ensures that the algae mass is concentrated, which is important for the following processing steps.

Step 4: Freezing the Spirulina

After separation from the water, the algae are collected and immediately frozen. Freezing is an important step because it preserves the quality of the Spirulina by stopping the biological activity and preventing any growth of unwanted microorganisms. Frozen Spirulina can be stored until it is ready for further processing.

Step 5: Freeze-drying

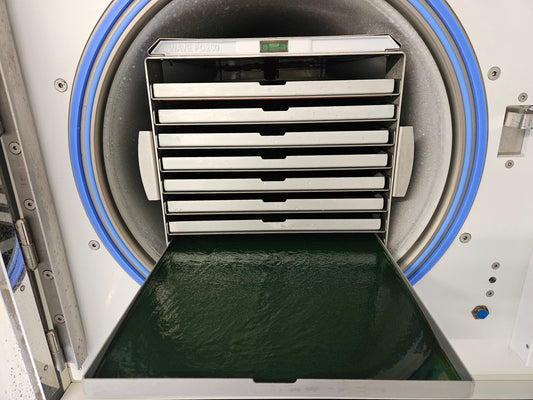

The frozen Spirulina is then subjected to a process called freeze-drying. Freeze-drying is a method of removing water from a product by first freezing it and then reducing the pressure to convert the frozen water directly into vapor. This process takes place in a freeze dryer.

Freeze-drying is a gentle drying technique that ensures that most of the nutrients and bioactive components of the Spirulina are retained. This results in a dry mass that is still rich in proteins, vitamins, minerals and antioxidants.

Step 6: Grind to Powder

The final step in the Spirulina production process is grinding the dried mass into a powder. This is done using a mill that grinds the dried Spirulina into a uniform powder. Grinding is a crucial step because it determines the texture and consistency of the final product, making it easy to add to foods and supplements.

Quality Control and Packaging

After milling, the Spirulina powder undergoes strict quality control to ensure it meets nutritional and safety standards. Samples of the powder are tested for contaminants and nutritional content to ensure the product is safe to consume and meets specifications.

After quality control, the Spirulina powder is packaged in airtight containers to preserve freshness and nutritional value. The packaging is designed to protect the Spirulina from light, moisture and air, which can affect the quality of the product.

Conclusion

The production process of Spirulina is a complex and carefully regulated process that starts in photobioreactors and ends with the grinding of the dried algae into powder. By carefully monitoring each step in this process, producers can deliver high-quality, food-safe Spirulina that is rich in nutrients. This approach ensures that Spirulina maintains its reputation as a superfood and contributes to a healthy diet. The continuous innovation and improvement of production techniques promise a bright future for Spirulina and other microalgae in the food industry.